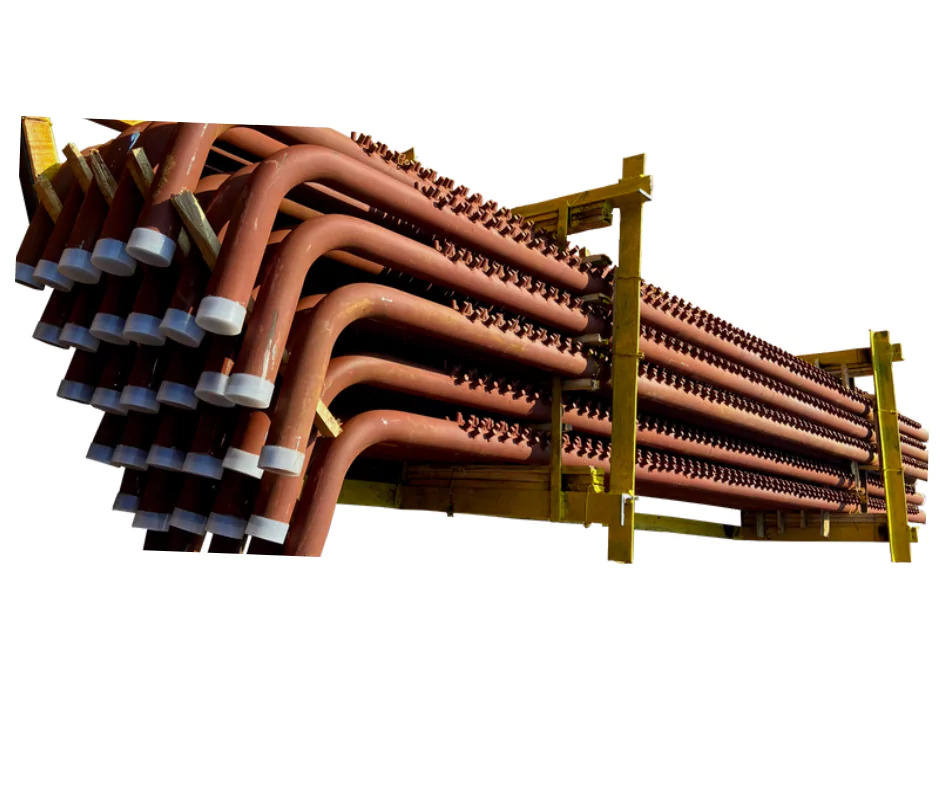

Super Heater Coils

Product Details:

- Storage Dry, Covered Area; Protect from Corrosion

- Melting Point Depends on Material (Typically 1400C for Alloy Steel)

- Heavy Metal (%) Depends on Material Composition

- HS Code 84029090

- Color Metallic Grey/Silver

- Smell Odorless

- Solubility Insoluble in Water

- Click to View more

Super Heater Coils Price And Quantity

- 1 Unit

- 100000 INR/Unit

Super Heater Coils Product Specifications

- Non-toxic

- Super Heater Coils

- Long Service Life (Depending on Application)

- Insoluble in Water

- Heat Transfer / Thermal Power Plants / Boilers

- Industrial Grade

- Tube/Coil Form

- N/A (Industrial Component)

- 84029090

- Depends on Material Composition

- Odorless

- Metallic Grey/Silver

- Depends on Material (Typically 1400C for Alloy Steel)

- Dry, Covered Area; Protect from Corrosion

- Finned / Plain / Radiant Super Heater Coils

- Solid (Metallic)

Super Heater Coils Trade Information

- Vadodara

- Cash in Advance (CID)

- 10 Unit Per Day

- 7 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Standard Packing

- Asia

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- ISO

Product Description

Superheater Coils for Boilers

Superheater coils are critical components in steam boilers used to increase the temperature of saturated steam without raising its pressure. They are typically installed in the hottest part of the flue gas path to absorb maximum heat and turn saturated steam into superheated steam.

What Are Superheater Coils?

Superheater coils are high-temperature heat exchangers made of specially designed tubes that carry saturated steam from the boiler drum. These coils are heated by combustion gases to produce superheated steam, which is ideal for driving turbines in power plants or for industrial processes.

Purpose:

-

Increases thermal efficiency

-

Produces dry, high-energy steam

-

Prevents turbine blade erosion (from wet steam)

-

Improves cycle efficiency in power generation (Rankine cycle)

Types of Superheaters:

-

Radiant Superheaters:

-

Located directly in the furnace zone

-

Exposed to radiant heat

-

Higher heat flux, risk of overheating

-

-

Convection Superheaters:

-

Located in the flue gas path

-

Heated by convection

-

Lower heat flux, more stable operation

-

-

Pendant and Horizontal Superheaters:

-

Orientation based on boiler design

-

Pendant: hanging vertically

-

Horizontal: laid out in rows above the furnace or convective path

Materials Used:

Because they operate at very high temperatures and pressures, superheater coils are made from high-alloy steels:

-

T11 / T22 (1.25Cr-0.5Mo / 2.25Cr-1Mo) for medium temps

-

TP304 / TP316 (Stainless Steels) for higher corrosion resistance

-

Inconel or other high-nickel alloys for extreme cases

Inspection & Maintenance:

-

Visual inspection for bulging or cracks

-

Ultrasonic thickness testing

-

Temperature monitoring

-

Boiler water treatment to prevent scaling

-

Steam flow checks to avoid starvation

Applications:

-

Thermal power plants

-

Industrial boilers (refineries, paper mills, chemical plants)

-

Marine boilers

-

Heat recovery systems

Key Design Considerations:

-

Steam pressure & temperature

-

Flue gas temperature

-

Steam flow rate

-

Material selection

-

Tube size & coil geometry

Precision Manufacturing & Material Range

Super Heater Coils are crafted with meticulous attention to material selection and dimensional accuracy. Available in carbon steel, alloy steel (such as SA213 T22 and T91), and premium-grade stainless steels, these coils can be seamlessly or welded to meet specific application requirements. Their manufacturing is guided by global standards, ensuring reliability and adaptability in high-temperature industrial operations.

Engineered for Demanding Environments

Designed to withstand pressures up to 150 kg/cm2 and temperatures reaching 650C, Super Heater Coils excel in rigorous operational settings. Their robust resistance to corrosion and high weldability contribute to consistent performance in boilers, heat exchangers, and power generation facilities, enhancing operational efficiency over long service lifespans.

Customizable Design & Versatile Applications

With options for coil type (finned/plain/radiant) and tailored dimensions (diameter, thickness, length), Super Heater Coils provide versatility for diverse industries, from power plants and petrochemicals to manufacturing. Their solid, metallic form and proven material grades ensure effective heat transfer, supported by protective storage and easy integration into existing systems.

FAQ's of Super Heater Coils:

Q: How are Super Heater Coils manufactured to meet custom size requirements?

A: Super Heater Coils are produced using advanced fabrication methods, including seamless or welded processes, allowing for customization of outer diameter (25-76.2 mm), tube thickness (2-10 mm), and lengths up to 12 meters. This ensures a precise fit for your specific boiler or heat exchanger needs.Q: What are the main benefits of using Super Heater Coils in power plants and boilers?

A: These coils offer superior heat transfer efficiency, high corrosion resistance (dependent on selected material), and can handle extreme pressures and temperatures. Their design enhances energy output and equipment longevity, making them ideal for critical power generation and industrial processes.Q: Where are Super Heater Coils commonly used?

A: Super Heater Coils are predominantly used in boilers, heat exchangers, steam power plants, and petrochemical industries throughout India and globally. Their robust construction and versatility make them suitable for a wide range of thermal and energy-based applications.Q: What processes are involved in ensuring corrosion resistance and durability?

A: Material choice, such as high-grade alloy or stainless steel, combined with heat treatments like annealing, normalizing, or tempering, enhances corrosion resistance and strength. Protective storage in dry, covered conditions further prolongs service life.Q: When should you opt for finned versus plain Super Heater Coils?

A: Finned coils are ideal for applications requiring increased heat transfer surface area, while plain coils are suited for standard heat transfer needs or when space constraints are minimal. Selection depends on the specific thermal duty and design of the system.Q: How should Super Heater Coils be stored before installation?

A: Coils should be kept in a dry, covered area to prevent corrosion. Proper storage ensures that their metallic surfaces remain intact and free from moisture-induced damage prior to integration into industrial equipment.Q: What standards govern the manufacturing and quality assurance of Super Heater Coils?

A: Production strictly adheres to internationally recognized standards, including ASME, ASTM, DIN, BS, and IS, ensuring quality, safety, and performance consistency across industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Boiler Pressure Part' category

|

SHREE NARAYAN ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese