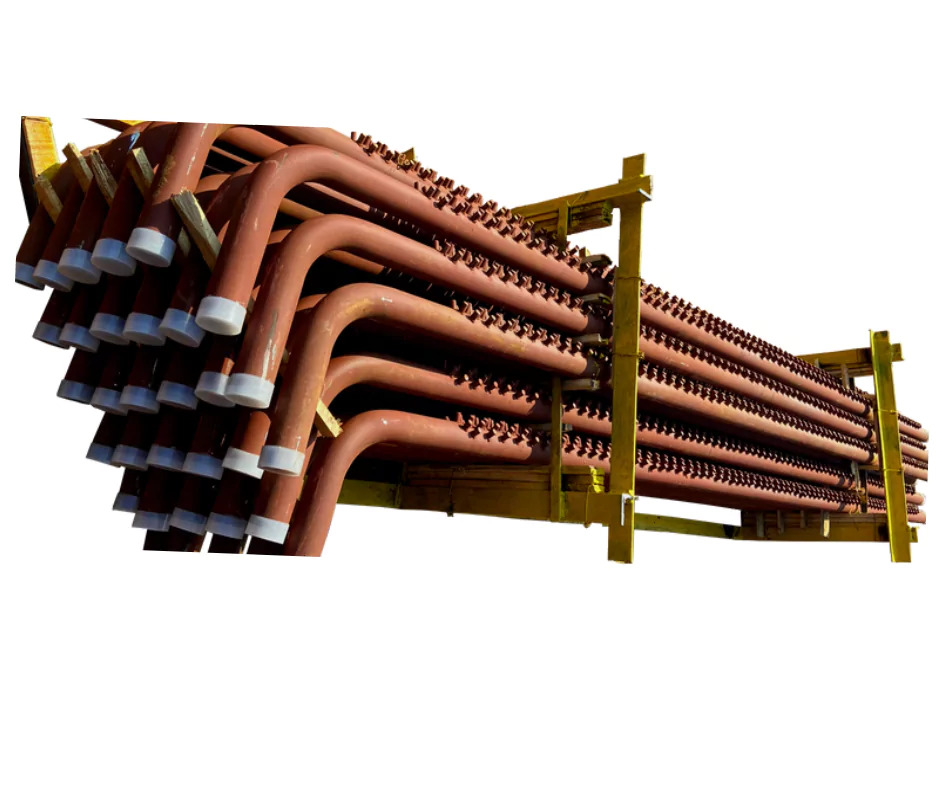

Boilers Bed Coils ( with or without stud)

Product Details:

- HS Code 84029020

- Poisonous Non-Poisonous

- Color Metallic Grey/Black

- Solubility Insoluble

- Smell Odorless

- Storage Dry Storage, Covered Area

- Shelf Life Long Term (if properly stored)

- Click to View more

Boilers Bed Coils ( with or without stud) Price And Quantity

- 1 Unit

- 100000 INR/Unit

Boilers Bed Coils ( with or without stud) Product Specifications

- Boiler Bed Construction and Repair

- 84029020

- Industrial

- Solid (Pipe/Coil)

- Tube Coils

- Insoluble

- Odorless

- Metallic Grey/Black

- Non-Poisonous

- With or Without Stud

- Dry Storage, Covered Area

- Long Term (if properly stored)

Boilers Bed Coils ( with or without stud) Trade Information

- Vadodara

- Cash Advance (CA), Cash in Advance (CID)

- 10 Unit Per Day

- 7 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Standard Packing

- Asia

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- ISO

Product Description

Boiler Bed Coils with or without studs

Boiler Bed Coils are crucial components used in fluidized bed combustion (FBC) boilers, especially in atmospheric fluidized bed combustion (AFBC) and circulating fluidized bed combustion (CFBC) systems. Heres a breakdown of what they are, how they work, and their key features

What Are Boiler Bed Coils?

Boiler bed coils are tubular heat exchangers located in the combustion bed of a fluidized bed boiler. These coils are submerged in the fluidized bed material, where intense heat transfer occurs due to the fluidized state of the fuel and bed material (typically sand or ash).

Purpose and Function:

-

Heat Transfer:

Bed coils absorb radiant and convective heat directly from the fluidized bed, preheating water or generating steam. -

Steam Generation:

Often used for evaporating water into steam in the lower temperature zones of the boiler, especially in low-pressure boilers. -

Efficiency Improvement:

They enhance boiler thermal efficiency by utilizing the high heat exchange capacity of the fluidized bed.

Design Features:

-

Material:

Typically made of carbon steel or alloy steel, depending on the operating temperature and pressure. -

Shape and Layout:

U-shaped or serpentine coils, tightly spaced to maximize surface area in the fluidized zone. -

Mounting:

Installed horizontally or vertically inside the combustion chamber.

Operating Conditions:

-

Temperature: 800C to 900C

-

Pressure: Varies depending on boiler design (can be 10 100+ bar)

Common Applications:

-

Thermal power plants

-

Captive power plants in industries

-

Biomass and waste-to-energy boilers

-

Industrial heating systems

Summary Table:

| Parameter | Details |

|---|---|

| Function | Heat transfer / Steam generation |

| Boiler Type | FBC (AFBC/CFBC) |

| Material | Carbon steel, Alloy steel |

| Risks | Erosion, scaling |

| Location | Inside fluidized bed |

| Orientation | Horizontal or vertical |

High-Quality Materials for Demanding Conditions

Boiler Bed Coils are crafted from industrial-grade carbon steel or alloy steel, ensuring durability and reliable performance under high stress. These materials are chosen for their ability to withstand intense heat and pressure, making them suitable for the rigorous demands of boiler bed construction and repair.

Customizable Dimensions and Advanced Manufacturing

Each coil is manufactured using welded, bent, or seamless techniques to match specific customer requirements. Options for outer diameter, wall thickness, and length provide tailored solutions for various boiler types. Studded or plain coils are available, with standard stud sizes to suit your application.

Strict Quality Control for Safety and Longevity

Every coil undergoes extensive hydrostatic and radiographic testing to guarantee integrity under operational pressures. Quality is further assured through careful surface treatmentssuch as sandblasting, painting, or special coatingsto ward off corrosion and prolong the products service life.

FAQs of Boilers Bed Coils ( with or without stud):

Q: How are Boiler Bed Coils used in boilers?

A: Boiler Bed Coils are installed within the combustion chamber of boilers like CFB and AFBC types. Their primary role is to facilitate heat transfer and support the bed material during combustion. Coils can be supplied with or without studs, depending on the specific application and ash retention needs within the boiler bed.Q: What customization options are available for these coils?

A: Dimensions like outer diameter (32mm to 76mm), wall thickness (3mm to 8mm), and length (typically 2m to 6m) can be tailored to meet your boilers design. You can also choose between carbon steel or alloy steel, with or without welded studs, and select surface treatments such as anti-corrosive coatings to match your operational requirements.Q: When should I use coils with welded studs?

A: Coils with welded studs are typically selected for applications needing enhanced support for refractory or bed material within the boiler. The studs improve ash retention and heat distribution, making them ideal for high-performance and heavy-duty combustion systems.Q: Where can Boiler Bed Coils be installed?

A: These coils are designed for use in circulating fluidized bed (CFB), AFBC, and other types of combustion boilers. Their robust construction allows installation in both new installations and replacement projects in boilers across power plants and industrial facilities.Q: What testing and certification are provided for quality assurance?

A: All coils are subjected to hydrostatic and radiographic testing to confirm they withstand high pressure and ensure structural integrity. Quality documentation and certifications are provided for every batch to meet safety and compliance standards.Q: How do Boiler Bed Coils resist heat and corrosion?

A: The materials usedcarbon steel or alloy steelare chosen for their natural ability to endure elevated temperatures. Optional anti-corrosive coatings and surface treatments further enhance resistance against oxidation and wear, extending the life of the coils even in harsh operating environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Boiler Pressure Part' category

|

SHREE NARAYAN ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese