Boiler Headers

Product Details:

- Smell Odorless

- HS Code 8402

- Solubility Insoluble in water

- Shelf Life More than 25 Years (Subject to corrosion protection)

- Color Metallic Grey / Black Painted / As per requirement

- Poisonous NO

- Storage Store in dry, indoor environment to prevent corrosion

- Click to View more

Boiler Headers Price And Quantity

- 1 Unit

- 100000 INR/Unit

Boiler Headers Product Specifications

- Metallic Grey / Black Painted / As per requirement

- More than 25 Years (Subject to corrosion protection)

- Industrial Grade

- Depends on material (e.g., 1400C for alloy steel)

- Steam and water circulation in boilers

- NO

- Store in dry, indoor environment to prevent corrosion

- Boiler Header

- Cylindrical, Welded or Seamless Pipe

- 8402

- Insoluble in water

- Odorless

- Solid (Metallic)

Boiler Headers Trade Information

- Vadodara

- Cash in Advance (CID)

- 10 Unit Per Day

- 7 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Standsard Packing

- Asia

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- IBR

Product Description

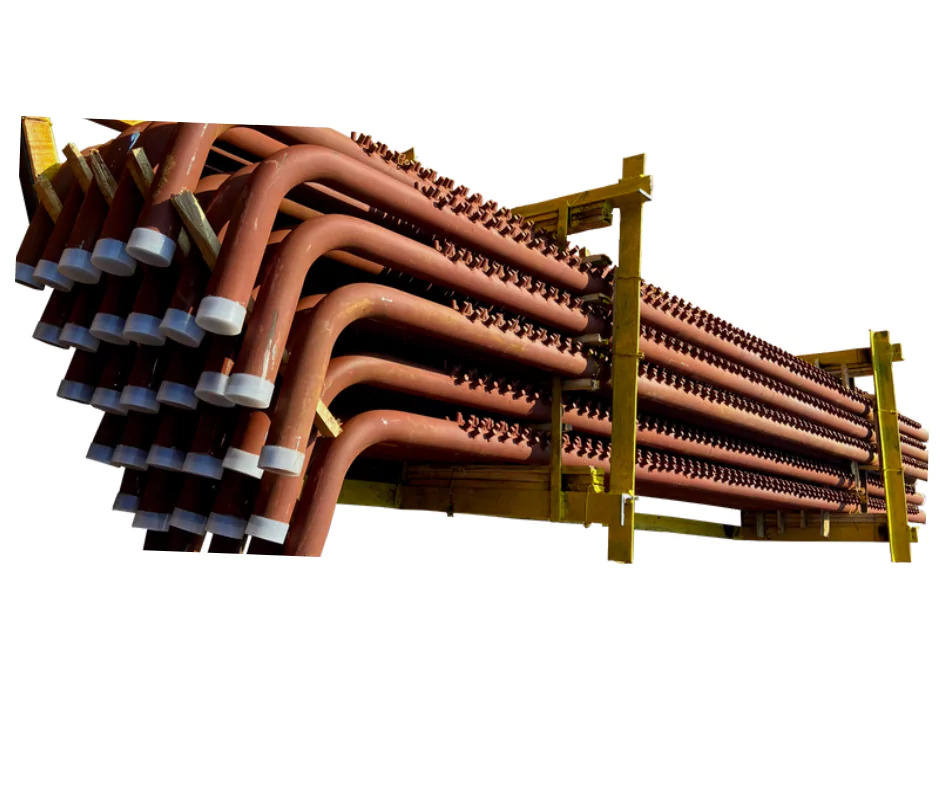

Boiler Headers Explained

Boiler headers (also called manifolds) are thick-walled pressure vessels used to collect or distribute steam, water, or flue gases within a boiler system. They serve as central nodes in high-pressure piping systems and play a critical role in ensuring balanced flow and thermal efficiency.

What Are Boiler Headers?

A boiler header is a large cylindrical pipe (horizontal or vertical) that connects multiple smaller tubes or coils (e.g., economizer, water wall, superheater, or reheater coils). Headers manage the flow of fluid (steam or water) between different sections of the boiler.

Types of Boiler Headers:

| Type | Function | Connected To |

|---|---|---|

| Steam Header | Collects or distributes steam | Superheater, turbines, process lines |

| Water Header | Distributes water to or collects from water wall tubes | Mud drum, downcomers |

| Economizer Header | Handles feedwater in/out of economizer coils | Feedwater lines |

| Superheater Header | Distributes saturated steam to superheater coils or collects superheated steam | Superheater tubes |

| Reheater Header | Involved in reheating steam | High- and low-pressure turbine circuits |

Functions:

-

Flow distribution or collection

-

Pressure equalization

-

Temperature regulation

-

Facilitating inspection, control, and maintenance

-

Preventing thermal shocks and flow imbalances

Construction Details:

-

Material: High-grade alloy or carbon steel (e.g., SA-106 Gr B, SA-335 P11/P22, etc.)

-

Design Pressure & Temp: Must meet ASME Section I or equivalent codes

-

Ends: Typically flanged or beveled for welding

-

Orientation: Horizontal (most common) or vertical

Boiler Header Locations:

-

Water Wall Headers: At the top and bottom of the boiler furnace

-

Superheater Headers: Before and after superheater coils

-

Economizer Headers: At inlet and outlet of economizer banks

-

Main Steam Header: Final outlet from the boiler to the plant/turbine

Maintenance and Inspection:

-

Non-destructive testing (NDT): Ultrasonic, radiographic, magnetic particle

-

Visual inspection of welds and joints

-

Hydrostatic pressure testing

-

Cleaning and descaling

Design Considerations:

-

Number and angle of tube stubs

-

Internal baffles or flow restrictors

-

Drain & vent provisions

-

Thermal expansion allowances

-

Material strength at high pressure/temperature

Robust Material & Construction

Boiler Headers are fabricated using seamless carbon steel or alloy steel such as SA-106 and SA-335, offering reliability and durability under extreme conditions. With diameters up to 800 mm and advanced welding or flanged connections, they are designed to accommodate high-pressure environments and rigorous operational demands in industrial settings.

Precision Testing & Inspection

Each Boiler Header undergoes comprehensive hydrostatic, radiographic, and ultrasonic testing to assure integrity and safety. These inspections guarantee that every unit meets high standards for performance, minimizing risk and ensuring long service life in critical applications like power generation and steam distribution.

Custom Solutions for Diverse Applications

We offer customized Boiler Headers to fit unique design and operational workflows. Whether you need specific sizes, working pressures, fabrication standards, or surface finishes, our engineering team collaborates with clients to deliver tailored solutions for power plants, industrial boilers, and steam systems.

FAQ's of Boiler Headers:

Q: How are Boiler Headers manufactured to withstand high working pressures and temperatures?

A: Boiler Headers are fabricated from seamless carbon steel or alloy steel (SA-106, SA-335), materials chosen for their strength at pressures up to 200 bar and temperatures up to 560C. Precise welding, flanged connections, and strict adherence to ASME or IBR standards ensure their resilience in demanding environments.Q: What is the process for inspecting and testing Boiler Headers before delivery?

A: Each Boiler Header undergoes hydrostatic pressure testing to verify leak-proof performance, radiographic (RT) and ultrasonic (UT) inspections confirm weld integrity and wall thickness. Only after passing these stringent tests are the headers approved for shipment, ensuring operational safety and regulatory compliance.Q: When is customization available for Boiler Headers, and what can be tailored?

A: Customization is offered whenever project specifications differ from standard options. Clients can request modifications in diameter, end connections, surface finish, pressure ratings, and fabrication standards, allowing the header to perfectly match unique installation and operational requirements.Q: Where are Boiler Headers commonly used?

A: Boiler Headers are integral to steam and water circulation in power plants, industrial boilers, and steam distribution systems. Their robust construction and adaptability make them vital in energy generation facilities across India and globally.Q: How should Boiler Headers be stored and maintained to maximize their shelf life?

A: Headers should be stored in a dry, indoor environment to prevent corrosion, and surface finishes such as painting or anti-corrosive coatings add protection. Regular inspections and adherence to storage guidelines contribute to a service life exceeding 25 years.Q: What benefits do Boiler Headers offer for steam distribution systems?

A: Boiler Headers enable efficient, uniform distribution of steam and water, enhancing overall system stability and performance. Their robust material and testing ensure reliability, while customization allows for seamless integration with existing infrastructure, minimizing downtime and facilitating long-term operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Boiler Pressure Part' category

|

SHREE NARAYAN ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese