Boiler Waterwall Panels

Product Details:

- Poisonous NO

- Color Black (coating or as-rolled steel)

- Storage Covered, dry and corrosion-free area

- HS Code 84029090

- Type Boiler Waterwall Panel

- Grade Industrial

- Usage Steam generation, heat transfer in boilers, power plants, and process industry boilers

- Click to View more

Boiler Waterwall Panels Price And Quantity

- 10 Unit

- 100000 INR/Unit

Boiler Waterwall Panels Product Specifications

- 84029090

- Covered, dry and corrosion-free area

- Black (coating or as-rolled steel)

- Industrial

- NO

- Steam generation, heat transfer in boilers, power plants, and process industry boilers

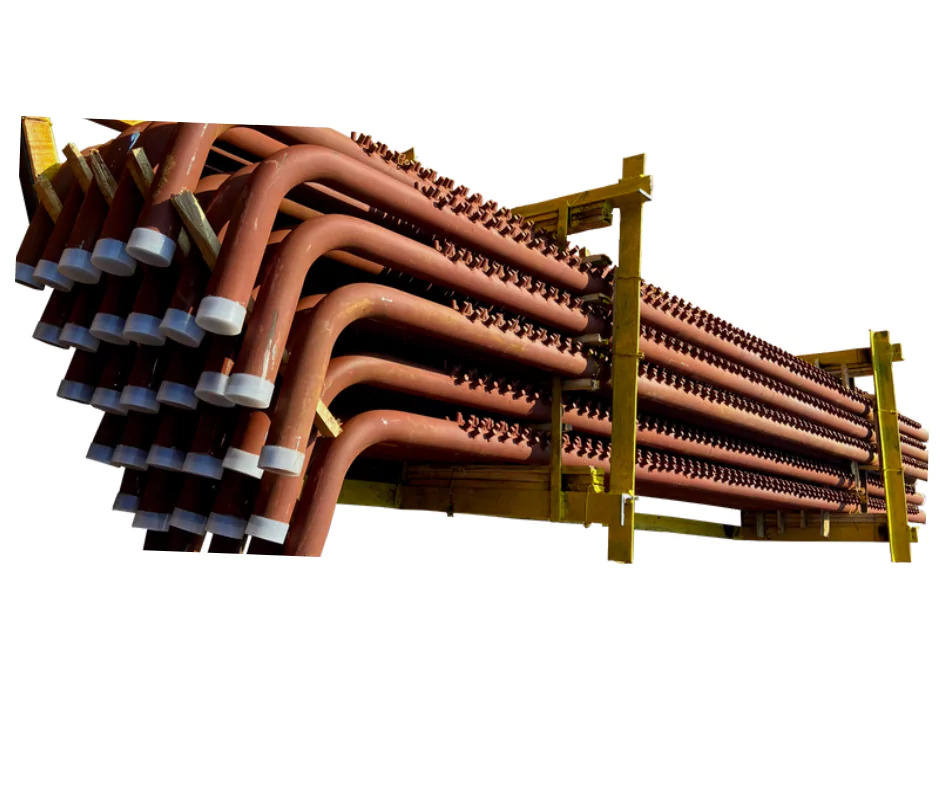

- Rectangular welded panel of seamless/ERW tube and fin bar

- Boiler Waterwall Panel

- Solid (Tube and fin welded assembly)

Boiler Waterwall Panels Trade Information

- Vadodara

- Cash in Advance (CID)

- 10 Unit Per Week

- 7 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- standard

- Asia

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- IBR

Product Description

Boiler Water Wall Panels Full Overview

Boiler water wall panels are vertical arrays of tubes placed along the inside walls of a boiler furnace to absorb radiant heat from the combustion process. They form a heat-absorbing enclosure around the furnace and are a critical part of modern water-tube boilers.

What Are Water Wall Panels?

Water wall panels consist of closely spaced boiler tubes that carry water or steam-water mixture, welded together with fins or membrane strips to form solid, gas-tight panels. They are exposed to direct radiation from the flame and act as:

-

Structural enclosure of the furnace

-

Primary heat absorbing surface

-

Pathway for water circulation to generate steam

Construction Features:

| Component | Description |

|---|---|

| Tubes | Usually carbon steel or low-alloy steel; vertical; 1.5 to 2.5" OD |

| Fins/Membranes | Welded between tubes for strength, support, and to create a gas-tight seal |

| Panel Size | Custom to boiler design; pre-fabricated for easy site assembly |

| Spacing | Close tube pitch (center-to-center distance), often 3 to 4 inches |

Materials Used:

-

Tube Material:

-

SA-210 Gr A1 (carbon steel)

-

SA-213 T11, T22 (for higher temperature zones)

-

Stainless steel (in corrosive or high-temp zones)

-

-

Filler Strip (Membrane/Fins): Same or compatible alloy as tubes

Types of Water Wall Construction:

| Type | Description |

|---|---|

| Bare Tube Walls | Tubes without any fins or membranes; used in older designs |

| Membrane Walls | Tubes welded together with metal strips to form leak-proof walls |

| Studded Walls | Tubes with studs for refractory attachment; used in fluidized bed or waste boilers |

Functions:

-

Absorb Radiant Heat Account for 30 to40% of total heat transfer in the boiler

-

Steam Generation Water inside the tubes begins to boil and form a steam-water mixture

-

Protect Furnace Walls Prevent damage from extreme heat

-

Improve Efficiency By converting radiant heat directly into steam

Circulation:

-

Natural or assisted by circulating pumps

-

Water from the mud drum rises through water wall tubes to the steam drum

-

Steam is separated and sent to superheater; water recirculates

Maintenance & Inspection:

-

Visual inspection during shutdowns

-

Non-destructive testing (NDT): UT, MT, RT

-

Hydrostatic pressure tests

-

Soot blowing (external cleaning)

-

Chemical cleaning (internal)

Design Considerations:

-

Boiler pressure & temp

-

Fuel type (coal, biomass, gas)

-

Heat flux zones (roof tubes require special attention)

-

Circulation type (natural vs forced)

Benefits of Membrane Water Wall Panels:

-

Gas-tight (no need for refractory in furnace walls)

-

Faster heat absorption

-

Lower maintenance (no refractory damage)

-

Pre-fabricated panels reduce field installation time

-

Improved boiler reliability and efficiency

Typical Specs:

| Parameter | Range |

|---|---|

| Tube OD | 38 to 63.5 mm (1.5 to 2.5) |

| Wall Thickness | 3 to 6 mm |

| Tube Pitch | 75 to 100 mm center-to-center |

| Panel Height | Up to 20 meters or more |

| Material Grades | SA-210, SA-213, TP304, etc. |

Tailored Panel Engineering

Our panels are manufactured precisely to client-specified drawings, accommodating a range of tube diameters, wall thicknesses, and fin bar dimensions. Whether your application demands robust Alloy Steel panels or specific coating solutions, each unit adheres to the strictest international quality codes, ensuring a reliable fit for any boiler system.

Stringent Testing and Compliance

Every waterwall panel undergoes comprehensive hydrostatic, pneumatic, dye-penetrant, and ultrasonic testing. Adherence to ASME, IBR, and ISO 9001 ensures maximum reliability and safety, while anticorrosive paint or coating protects panels from challenging operating conditions and atmospheric exposure.

Optimal Performance and Usage

Designed for high-efficiency heat transfer and steam generation, these panels are ideal for industrial boilers in power plants and process industries. Their solid construction not only minimizes heat losses but also ensures a longer service life and reduced maintenance, making them a backbone component in modern boiler systems.

FAQ's of Boiler Waterwall Panels:

Q: How are Boiler Waterwall Panels manufactured to ensure quality and compliance?

A: Boiler Waterwall Panels are custom-manufactured using seamless or ERW tubes welded with fin bars, utilizing high-frequency resistance welding or TIG/MIG techniques. Strict adherence to ASTM, IS, EN, and ASME/IBR codes, along with ISO 9001 certification, ensures every panel meets rigorous industry standards.Q: What is the process for selecting the right tube material and dimensions?

A: The tube material-Carbon Steel or Alloy Steel-is chosen based on operating conditions such as temperature and pressure. Tube outer diameters (38 mm to 76.1 mm) and wall thickness (3 mm to 12 mm) are customized per client drawings and system requirements to achieve optimal heat transfer and mechanical strength.Q: Where can Boiler Waterwall Panels be used, and what are their main applications?

A: These panels are primarily utilized in steam generation and heat transfer within industrial boilers found in power plants, energy facilities, and process industries. Their robust construction and reliable performance make them suitable for both new boiler installations and retrofits.Q: What types of testing are performed on Boiler Waterwall Panels for reliability?

A: Each panel undergoes hydrostatic, pneumatic, dye-penetrant, and ultrasonic testing to verify structural integrity, leak-proof operation, and weld quality, ensuring safe and long-lasting service.Q: Which benefits do membrane type waterwall panels offer compared to conventional designs?

A: Membrane waterwall panels provide superior heat transfer efficiency, reduced gas leakage, enhanced mechanical strength, and easier maintenance. Their welded fin structure improves panel rigidity and protects against high-temperature deformation.Q: How should Boiler Waterwall Panels be stored before installation?

A: Panels should be stored in a covered, dry, and corrosion-free environment to maintain their surface integrity and prevent rusting or coating deterioration prior to installation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Boiler Pressure Part' category

|

SHREE NARAYAN ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese