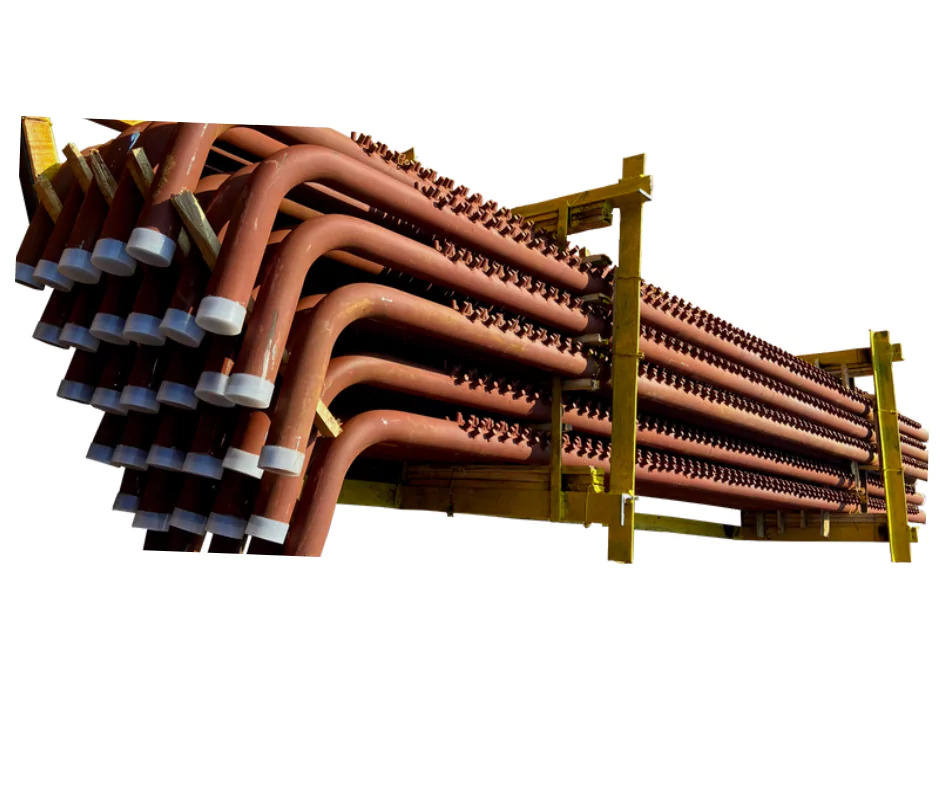

Boiler Swaged Tubes

Product Details:

- Storage Store in a dry place, protected from moisture

- HS Code 73043110

- Color Black (as per surface treatment)

- Smell Odorless

- Poisonous NO

- Type Swaged Tube

- Grade Boiler Grade

- Click to View more

Boiler Swaged Tubes Price And Quantity

- 10 Unit

- 100000 INR/Unit

Boiler Swaged Tubes Product Specifications

- Used in boilers, heat exchangers, super heaters, and other high-pressure applications

- Swaged Tube

- Hollow Section Tubes with Swaged/Reduced Ends

- Solid (Tube)

- Boiler Grade

- NO

- Odorless

- Store in a dry place, protected from moisture

- 73043110

- Black (as per surface treatment)

Boiler Swaged Tubes Trade Information

- Vadodara

- Cash Advance (CA), Cash in Advance (CID)

- 100 Unit Per Day

- 7 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Industrial Pack

- Asia

- , All India, South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Lakshadweep, Mizoram, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal

- IBR Certified

Product Description

Boiler Swaged Tubes Explained

Swaged tubes in a boiler are tubes that have been mechanically reduced in diameter at one or both ends to allow a snug fit into headers, drums, or other tubes of smaller diameter. Swaging is done to ensure tight mechanical joints, promote better weld connections, or allow for expansion fitting.

What Are Swaged Boiler Tubes?

-

Swaging is a metal forming process that reduces the outer diameter (OD) of a tube by cold or hot mechanical deformation.

-

In boilers, swaged tube ends are used when the tube needs to connect to a drum hole or header that is smaller in diameter than the tube body.

-

Its a common practice in water-tube boilers, especially in superheater, economizer, and water wall tubes.

Purpose of Swaging:

-

Join different tube sizes (e.g., 2" tube swaged down to fit a 1.5" header)

-

Ease of installation in tight or restricted boiler spaces

-

Provide smooth internal transitions to reduce turbulence

-

Prepare tube ends for welding, expansion, or rolling into drums or headers

Swaging Process:

| Method | Description |

|---|---|

| Cold Swaging | Performed at room temperature using dies and hydraulic or mechanical presses |

| Hot Swaging | Done at elevated temperatures to reduce force and avoid cracking, especially in alloy steels |

| Rotary Swaging | Tube is inserted into rotating dies that hammer the outside to reduce diameter |

| Tapered Swaging | Used to form a smooth tapered profile at the end of the tube |

Tube Materials:

Swaging can be performed on most boiler tube materials:

-

Carbon steel (e.g., SA-210 Gr A1)

-

Alloy steel (e.g., T11, T22)

-

Stainless steel (e.g., TP304, TP316)

-

The material must maintain mechanical integrity after deformation.

Inspection & Quality Control:

-

Dimensional checks (OD, taper, wall thickness)

-

Visual inspection for cracks or scoring

-

Dye penetrant or magnetic particle testing for surface defects

-

Hardness tests (especially after cold swaging of hardened steels)

Best Practices:

-

Use proper lubrication to reduce surface damage during swaging

-

Allow post-forming heat treatment if required (for alloy steels)

-

Ensure uniform wall thickness after swaging

-

Select the correct die angle and taper for smooth transition

Typical Dimensions:

-

Original Tube OD: 1.5" to 3"

-

Swaged End OD: Reduced by 1/8" to 1/2", depending on fit

-

Swage Length: Usually 2" to 6", or custom per spec

Precision Manufacturing and Customization

Boiler Swaged Tubes are produced through advanced cold drawn or hot finished processes, followed by precise swaging to achieve reduced or specialty ends. Each tube can be customized for diameter, thickness, length, and end type in accordance with specific project drawings and standards, ensuring a tailored fit for high-pressure systems.

Durability and Superior Performance

These tubes are engineered to meet stringent tensile strength and high-pressure requirements of industrial boilers. The superior quality of carbon and alloy steel ensures lasting reliability, while the protective black paint or anti-rust oil coating safeguards against corrosion and extends service life.

Versatile Applications and Efficient Supply

Used extensively in boilers, heat exchangers, and super heaters, Boiler Swaged Tubes are essential for critical high-pressure applications. As a trusted importer, manufacturer, supplier, and trader, we ensure rapid delivery of customized orders across India, meeting diverse technical and operational demands.

FAQ's of Boiler Swaged Tubes:

Q: How are Boiler Swaged Tubes manufactured and what distinguishes the swaging process?

A: Boiler Swaged Tubes are produced using cold drawn or hot finished methods, with swaging applied at the tube ends to alter their diameter or shape as per customer specifications. This swaging process provides a seamless transition and enhances tube compatibility in boiler assemblies, ensuring a secure and leak-proof fit.Q: What industries typically use Boiler Swaged Tubes and for what applications?

A: These tubes are primarily utilized in power plants, chemical industries, and energy sectors for use in boilers, heat exchangers, super heaters, and other high-pressure systems. Their robust construction supports demanding thermal and pressure conditions, ensuring operational safety and efficiency.Q: When should I consider using Carbon Steel vs. Alloy Steel Boiler Swaged Tubes?

A: Carbon steel tubes are preferred for general high-pressure boiler applications where standard strength and moderate corrosion resistance suffice. Alloy steel tubes, with improved tensile strength and higher resistance to heat and corrosion, are ideal for more extreme conditions and critical applications requiring increased durability.Q: Where can I source Boiler Swaged Tubes in customized dimensions and material grades?

A: Boiler Swaged Tubes can be sourced from leading manufacturers, suppliers, and importers across India, including us. We offer comprehensive customization options for diameter, wall thickness, length, material grade, and finishing, conforming to ASTM, DIN, BS, and IS standards as per client requirements.Q: What is the recommended process for storing Boiler Swaged Tubes to maintain their quality?

A: To preserve the quality and prevent corrosion, it is advised to store Boiler Swaged Tubes in a dry environment protected from moisture. Tubes are typically coated with black paint or anti-rust oil and bundled with HDPE wraps or steel straps for secure storage and transit.Q: What are the benefits of choosing swaged ends for boiler tubes?

A: Swaged ends provide a tighter, more secure fit with adjoining components, reducing the risk of leakage and improving the overall integrity of high-pressure boiler systems. Custom swaging can match complex connection requirements, streamlining installation and minimizing downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Boiler Pressure Part' category

|

SHREE NARAYAN ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese