Do you need help? Here Us:

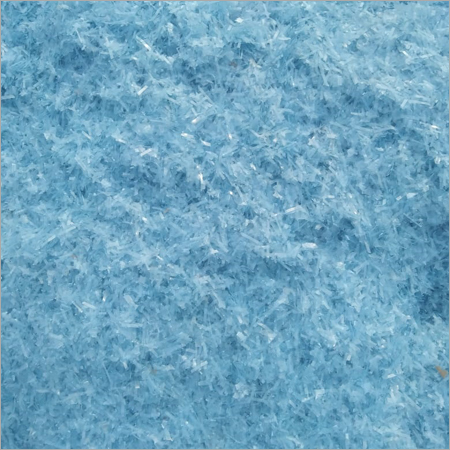

Clear PVC Scrap

50000.00 INR/Ton

Product Details:

- Usage Recycling, Manufacturing, Reprocessing

- Density 1.45 Gram per cubic centimeter(g/cm3)

- Plastic Type PVC (Polyvinyl Chloride)

- Type Industrial Scrap

- Size Variable, usually shredded or sheet form

- Shape Irregular, flakes or pieces

- Color Clear

- Click to View more

X

Clear PVC Scrap Price And Quantity

- 20000.00 - 90000.00 INR/Ton

- 50000.00 INR/Ton

- 5 Metric Ton

Clear PVC Scrap Product Specifications

- Bulk, as per order

- 1.45 Gram per cubic centimeter(g/cm3)

- Clear

- PVC (Polyvinyl Chloride)

- Industrial Scrap

- Irregular, flakes or pieces

- Variable, usually shredded or sheet form

- Recycling, Manufacturing, Reprocessing

Clear PVC Scrap Trade Information

- 100 Metric Ton Per Month

- 1 Week

Product Description

Clear PVC Scrap designed by us, is commonly utilized in injection shoe soles, shirk film, hoses, and refrigerators. Door gaskets, intumescent fire seals, wire and cable, traffic cones, pipes, and panels, among other things. PVC is one of the most widely used materials in today's world, and it is a necessity in many industries. Clear PVC Scrap is very much liked and highly appreciated by people, in the market. PVC is also utilized to substitute several other materials in order to save money.

High Purity, Versatile Industrial PVC Scrap

Our clear PVC scrap is notably high in purity and virtually free from contaminants, ensuring reliable performance in several manufacturing processes. With impressive physical properties and controlled moisture/ash content, it is trusted by leading pipe, film, and sheet producers. Shipped in convenient packaging, this scrap guarantees consistent outcomes in recycling and reprocessing environments, catering efficiently to bulk requirements.

Optimal Storage and Secure Packaging

To preserve quality, our PVC scrap is kept in an indoor, dry, and clean environment, mitigating the risks of moisture absorption or external pollution. Packaging options, such as jumbo bags or customized solutions, guarantee safe transit and storage, maintaining material integrity up to the point of use. This careful approach supports seamless operations for recyclers and manufacturers.

FAQ's of Clear PVC Scrap:

Q: How can clear PVC scrap be used in manufacturing?

A: Clear PVC scrap can be effectively utilized in manufacturing pipes, films, sheets, and profiles. Its physical properties, such as high tensile strength and hardness, make it ideal for recycling and reprocessing in these industrial applications.Q: What steps are involved in processing clear PVC scrap for reuse?

A: The scrap is typically sorted, washed, and shredded into flakes or irregular pieces. It is then melted and extruded, or pelletized, under controlled temperatures, maintaining a melt flow index of 4-8 g/10 min, to produce new PVC products or components.Q: When is the best time to store and process clear PVC scrap?

A: Clear PVC scrap should be stored and processed in an indoor environment, where it is dry and clean. Immediate storage after delivery and processing within a reasonable timeframe help retain its mechanical and chemical properties.Q: Where should clear PVC scrap be stored for optimal quality?

A: For maintaining high quality, the scrap must be kept indoors in a dry and clean setting. This storage approach helps prevent moisture uptake and contamination, ensuring consistent performance during reprocessing.Q: What are the advantages of using high purity PVC scrap?

A: Utilizing high purity PVC scrap reduces the risk of defects and ensures uniformity in the final products. Its low moisture and ash content also enhance process efficiency while minimizing machine wear and product inconsistencies.Q: How is clear PVC scrap packaged for delivery?

A: Clear PVC scrap is packaged in jumbo bags or tailored packaging as per customer requirements. These packaging options help ensure safety and convenience during transportation and storage.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'PVC Imported' category

|

SHREE NARAYAN ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese